According to foreign media reports, there may soon be another way to replace the finger tingling blood sugar test that diabetic patients must endure every day. Scientists from Shatra Aber have recently developed a method to measure blood sugar through the saliva of patients. Tape sensor. It is reported that the project is under the responsibility of Sahika Inal, a biologist of King Abdullah University of Science and Technology, Khaled Salama, electrical engineer, and Derya Baran, a materials scientist.

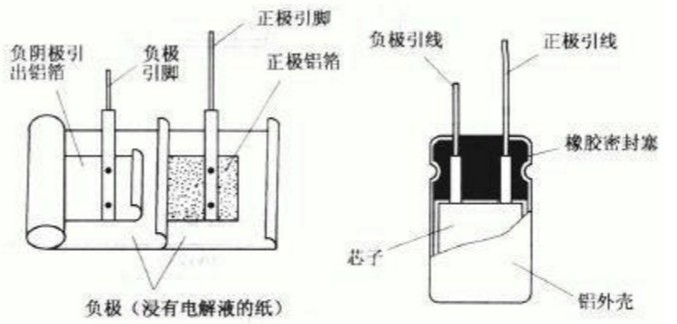

They first loaded a commercial ink containing a conductive polymer into an inkjet printer, and then used this ink to print a microelectrode pattern on a smooth paper web. Next, on top of the electrodes they printed an enzyme called glucose oxidase. Finally, they covered the whole thing with a perfluorosulfonic acid polymer film.

They first loaded a commercial ink containing a conductive polymer into an inkjet printer, and then used this ink to print a microelectrode pattern on a smooth paper web. Next, above the electrodes, they printed a layer of enzyme called glucose oxidase. Finally, they covered the entire object with a perfluorosulfonic acid resin (perfluorosulfonic acid) polymer film.

When saliva is transferred to the sensor, glucose in the body fluid reacts with glucose oxidase to produce an electrical signal. This signal is then received by the electrode and can also be read by another device - the intensity of the signal and the person providing the saliva The blood sugar level corresponds.

Although saliva contains substances such as ascorbic acid which usually interfere with the conductive polymer, the perfluorosulfonic acid resin film can prevent this from happening because it can repel the negative charge generated by these compounds. The film also increases the shelf life of the sensor, allowing glucose oxidase to remain active after storage for one month in a sealed bag.

Inaler said: "Optimization work will never stop on the project, so we try to make this system more powerful to detect other metabolites in biological fluids. We also hope to be able to print, self-powered The integration of the energy device into the sensor provides us with a more user-friendly platform to eliminate external batteries or wires.

Related research reports have been published on "Flexible Electronics".

Follow Me

英语

英语  中文

中文  德语

德语  韩语

韩语  日语

日语  波斯语

波斯语  葡萄牙语

葡萄牙语  俄语

俄语  西班牙语

西班牙语